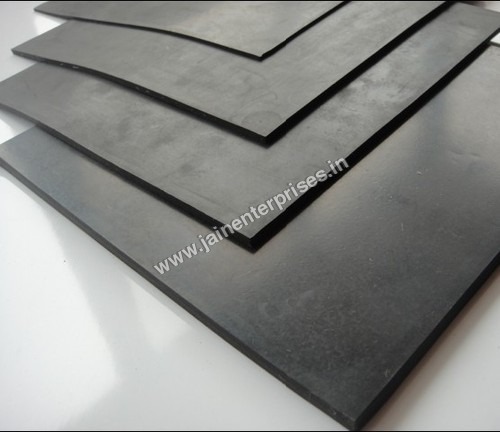

Natural Rubber Sheet

Price 100 INR/ Piece

Natural Rubber Sheet Specification

- Classification

- Natural Rubber Sheet

- Chemical Name

- Polyisoprene

- CAS No

- 9006-04-6

- Type

- Sheet

- Purity(%)

- 98%

- Application

- Industrial, Gasket, Flooring, Insulation, Sealing

- Color

- Black

- Physical Form

- Solid

- Grade

- Industrial Grade

- Appearance

- Smooth or Textured surface

Natural Rubber Sheet Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Natural Rubber Sheet

Natural Rubber Sheet

Owing to the support of our manpower and large shipping channel, we are the most preferred manufacturer and exporter of the Natural Rubber Sheet. With the availability in different sizes & thickness, these sheets are made by our experts using tested quality rubber. Find usage in varied industries, these sheets are offered to our clients at the reasonable prices. We are providing Natural Rubber Sheet to our clients within specified time frame.

Features:

- Excellent abrasion resistance

- Low crack growth

- Impeccable resilience

Further Details:

Good For:- Natural Rubber has many good characteristics. It has good compression set, high tear strength

Bad For:- Natural Rubber is not recommended for oil and solvent resistance

| Thickness | 0.5mm to 50mm |

| Width | Up to 1200mm |

| Length | Continuous length |

| Color | Black, Red or in desired color |

| Temp. | 20deg.C to +80deg.C |

| Hardness | Shore A 40 to 85 |

| Tensile Strength | 2Mpa |

| Elongation | 180% |

Versatile Applications

Natural Rubber Sheets are used in diverse industrial settings, serving as gaskets, flooring, insulation, and sealing solutions. Their adaptability in thickness, width, and length makes them ideal for custom jobs as well as standard installations, ensuring reliable performance for manufacturers and suppliers alike.

Optimized Performance

With robust physical properties like high tensile strength and significant elongation, these sheets withstand rigorous demands. Their specific gravity and low compression set enhance resilience, while the range of hardness supports multiple usage scenarios where flexibility or rigidity is required.

Resistance and Durability

Engineered to resist mild acids, alkalis, and salt water, Natural Rubber Sheets perform exceptionally in challenging environments. However, they should be avoided in contact with oils or hydrocarbons. The temperature range of -40C to +70C allows functionality in varied climates and applications.

FAQs of Natural Rubber Sheet:

Q: How can I select the right thickness and width for my application?

A: Determine your projects requirements and consult with the supplier to choose a thickness between 1 mm and 50 mm, and width up to 2 meters. This flexibility allows the sheets to be used for custom gaskets, insulation panels, or industrial seals.Q: What is the standard process for installing Natural Rubber Sheets?

A: Installation generally involves cutting the sheets to the desired size and adhering or fastening them onto surfaces as required. For applications like flooring or gasket making, its recommended to use compatible adhesives or mechanical fasteners for optimal results.Q: When should Natural Rubber Sheets not be used?

A: Avoid using these sheets where prolonged exposure to oils, hydrocarbons, or highly aggressive chemicals occurs, as they are not resistant to these substances. They perform best in environments with mild acids, alkalis, and salt water.Q: Where can Natural Rubber Sheets be applied effectively?

A: These sheets are suitable for use in industrial gasketing, flooring, insulation, and sealing applications. Their durability and resistance to certain chemicals make them ideal for manufacturing plants, workshops, and marine settings.Q: What are the benefits of using natural rubber for industrial purposes?

A: Natural rubber sheets offer excellent flexibility, high tensile strength, and substantial elongation, enabling reliable sealing, insulation, and shock absorption. Their low compression set ensures they retain shape and function under pressure.Q: How is the surface finish determined for Natural Rubber Sheets?

A: Surface finish, available as smooth or cloth, is selected based on the intended application. Smooth surfaces are ideal for sealing and insulation, while textured finishes enhance grip and reduce slippage for flooring applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese