Bus Body Profile

Price 100 INR/ Piece

Bus Body Profile Specification

- Width

- 34 mm

- Size

- Standard/Custom as per requirement

- Surface Finish

- Matte or anodized

- Style

- Rectangular, angular, or custom profiles

- Material

- Aluminum Alloy

- Resistance level

- High corrosion resistance

- Usage & Applications

- Bus body framing, window and door sections, exterior paneling, support frame

- Thickness

- 2.5 mm

- Feature

- Corrosion resistant, lightweight, easy installation

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Weight

- Approximately 1.5 kg/meter

- Components

- Main body frame, window channel, support ribs

- Hardness

- 65-75 HRB

- Water Absorption

- Negligible

- Length

- 6 meters (customizable)

- Color

- Silver/Grey (Natural Aluminum Finish)

- Tolerance

- 0.5 mm

- Part Type

- Profile Section

- Flame Resistance Level

- Basic flame retardant properties

- Product Type

- Bus Body Profile

- Thermal Conductivity

- 180-230 W/mK

- Tensile Strength

- 210-260 MPa

- Temperature Resistance

- Up to 120C

- Edging

- Deburred and smoothed edges

- Lead Time

- Within 7-15 days after order confirmation

- Weldability

- Excellent, suitable for MIG/TIG and Spot welding

- Compatibility

- Suitable for all standard bus models

- Packaging Type

- Bundle Wrapped with Protective Film

- Section Shape

- C-Channel, Hat Section, U-Channel, Z-Section

- Manufacturing Technique

- Cold Rolled/Hot Rolled/Extruded

- Bendability

- Good, suitable for shaping and fabrication

- UV Resistance

- Available with UV resistant coating

Bus Body Profile Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Customized packing

- Main Domestic Market

- All India

About Bus Body Profile

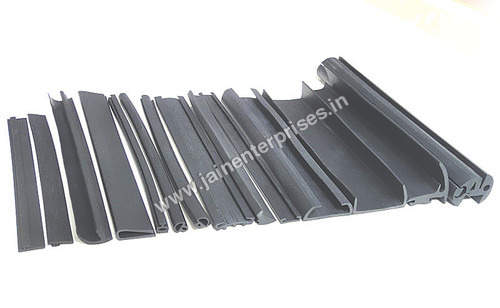

Bus Body Profile

Committed to garner maximum satisfaction of our clients, we are engaged in manufacturing and exporting Bus Body Profile. Made by our talented manpower using high grade quality materials, these products are widely used for making interiors of automobiles such as bus weather resistant. With the availability in diverse specifications, these products are offered to our clients at reasonable prices. Owing to our high-end quality Bus Body Profile, we have made huge client base across the market.

Features:

- Application specific design

- Perfect finishing

- Highly sustainable

Versatile Bus Body Profile Shapes

Our aluminum profiles are available in multiple section shapesincluding C-Channel, U-Channel, Hat, and Z-Sectionsto meet a wide range of bus design requirements. Customized profiles can be created for non-standard geometric needs, ensuring flexibility for manufacturers and suppliers in India.

Durable Material and High Performance

Made from robust aluminum alloys, our profiles combine a tensile strength of 210-260 MPa with high hardness (65-75 HRB) and exceptional corrosion resistance. This ensures long-term durability for bus body framing, window channels, exterior paneling, and support frames, even in challenging environments.

Efficiency in Manufacturing and Installation

Profiles are crafted using cold-rolled, hot-rolled, or extruded manufacturing techniques for superior finish and precise tolerances. The excellent bendability and weldability accommodate MIG, TIG, and spot welding, while smoothed, deburred edges support swift, safe installation.

FAQs of Bus Body Profile:

Q: How are the Bus Body Profiles manufactured?

A: The profiles are produced through advanced cold-rolled, hot-rolled, or extrusion techniques. This ensures uniformity in size, structural integrity, and a smooth surface finish for reliable performance in bus body applications.Q: What profiles and sizes are available for these bus sections?

A: We offer C-Channel, Hat Section, U-Channel, and Z-Section designs, in both standard and custom dimensions. The typical width is 34 mm, thickness is 2.5 mm, and length is 6 meters, but these can be customized to your requirements.Q: When can I expect delivery after placing an order?

A: Lead time for your order is typically within 7-15 days after confirmation, ensuring minimal delay in your production schedule without compromising on quality.Q: Where are these profiles best used within a bus structure?

A: These profiles are ideal for bus body framing, window and door sections, exterior paneling, and support frames. Their versatility allows compatibility with all standard bus models.Q: What are the benefits of choosing this aluminum alloy profile for bus manufacturing?

A: Key benefits include lightweight design, high corrosion and UV resistance, precise tolerances, good thermal conductivity, basic flame retardant properties, and easy installation, making them cost-effective and reliable for long-term use.Q: How can these profiles be joined or fabricated during assembly?

A: With deburred, smoothed edges and excellent bendability, the profiles support seamless MIG, TIG, or spot welding, allowing flexibility in assembly and fabrication processes.Q: What special protections or coatings are provided for these profiles?

A: Each order is shipped bundle-wrapped with a protective film to prevent surface damage. Additionally, UV-resistant coatings and anodized matte finishes are available for enhanced durability in harsh outdoor conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Profile Category

Extruded Rubber Profile

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Length : Up to 10 meters, customizable

Color : Black, available in other colors on request

Water Absorption : Low

Tolerance : 0.2 mm

EPDM Rubber Profiles

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Length : Up to 50 meters/roll (customizable)

Color : Black (other colors available on request)

Water Absorption : 2% (by weight)

Tolerance : 0.5 mm

Glass run rubber flock channel.

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Length : Rolls of 25 meters or customcut

Color : Black

Water Absorption : Negligible, less than 1%

Tolerance : 0.2 mm

Flocked Glass Run Channel

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Length : Up to 3 meters or custom

Color : Black

Water Absorption : <1%

Tolerance : 0.5 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese