Sand Blasting Hose

Price 100 INR/ Piece

Sand Blasting Hose Specification

- Weight

- Varies as per diameter and length

- Color

- Black with yellow/green/red stripe (as per manufacturer)

- Flame Resistance Level

- Not flame resistant

- Length

- Standard 18 meters or custom length

- Style

- Flexible, corrugated or plain

- Size

- Available in sizes from 12 mm to 50 mm inner diameter

- Thermal Conductivity

- Low

- Natural Rubber

- Yes, tube made from natural rubber compound

- Resistance level

- High abrasion resistance

- Tolerance

- 1 mm

- Feature

- Abrasion resistant, anti-static, weather resistant

- Components

- Tube, reinforcement, cover

- Material

- Natural and synthetic rubber with textile reinforcement

- Hardness

- 65 5 Shore A

- Density

- 1.5 Gram per cubic centimeter(g/cm3)

- Diameter

- 12 mm to 50 mm (inner)

- Usage & Applications

- Used for sand blasting in industrial cleaning, surface preparation, and rust removal tasks.

- Surface Finish

- Smooth or wrapped

- Part Type

- Hose pipe

- Rubber Type

- Natural and synthetic blend

- Thickness

- 3 mm to 7 mm (as per size)

- Water Absorption

- Minimal

- Temperature Resistance

- -40C to +70C

- Product Type

- Sand Blasting Hose

- Tensile Strength

- 180 kg/cm2 (Approx)

- Cover

- Black, abrasion and weather resistant rubber compound

- Working Pressure

- 12 Bar to 25 Bar (varies per size)

- End Connection

- Plain or with fittings as specified

- Manufacturing Standard

- IS 5894 / IS 3499 or as specified

- Burst Pressure

- Minimum 60 Bar

- Electrical Conductivity

- Anti-static properties available

- Minimum Bend Radius

- 6 times the nominal bore

- Shape

- Round

- Ozone Resistance

- Yes, good

- Reinforcement

- Multiple layers of high tensile synthetic textile plies

- Inner Tube Construction

- Black, smooth, highly abrasion resistant natural rubber

- Vacuum Resistance

- Not applicable or limited

- Shrinkage

- Negligible

Sand Blasting Hose Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Customized packing

- Main Domestic Market

- All India

About Sand Blasting Hose

Sand Blasting HoseWith in-depth knowledge and sound experience in this domain, we are manufacturing and exporting a wide stock of Sand Blasting Hose. We do not compromise with the quality of blasting hoses; hence these are manufactured by us using tested quality materials. Mainly supplied in shipyards, ordnance factory, steel fabrication, cylinder manufacturing units, manufacturing workshops and heavy engineering industries, Sand Blasting Hose is ideal for conveying sand, shots or diverse abrasive materials.

Features:

- Seamless finish

- Excellent stability

- Unmatched quality

Further Details:

| Lining | : | Uniform seamless tube of natural/synthetic/blend rubber compound of high tensile strength, excellent abrasion resistance and free from air blister, porosity and other defects. |

| Reinforcement | : | Plies of rubber impregnated woven textile or braiding of high strength natural/synthetic fibre. |

| Cover | : | Suitable rubber compound of cloth marked finish resistant to abrasion and weather. |

| Electric Bonding | : | A strand of copper wire is embedded between the reinforcement plies to provide electrical continuity throughout the length of the hose. |

Pressures:

Type 1 - W. P. 0.7 MPa & B. P. 3.5MPa.

Type 2 - W. P. 1.0 MPa & B. P. 5.0MPa.

| Nom. Bore | Tolerance on | Min. Thk. of | Min. Thk. of |

| 20.00 | ±0.75 | 6.3 | 1.50 |

| 25.00 | ± 1.25 | 6.3 | 1.50 |

| 31.50 | ± 1.25 | 6.3 | 1.50 |

| 38.00 | ± 1.50 | 6.3 | 1.50 |

| 45.00 | ± 1.50 | 6.3 | 1.50 |

| 50.00 | ± 1.50 | 6.3 | 1.50 |

- W.P. :Working Pressure, P.P. : Proof Pressure, B.P. : Burst Pressure, 1MPa : 10.2Kgf/Cm2 1Kgf/Cm2 :100KN/m2

- Length : Mandrel made hose upto 20 mtr., Moulded braided hose in continuos long length.

Superior Durability and Safety

Built for demanding sand blasting operations, this hose incorporates abrasion-resistant natural rubber and a weather-resistant cover to withstand harsh usage. Reinforced with multiple layers of high-tensile synthetic textiles, it provides dependable performance with minimal shrinkage, a high tensile strength of approximately 180 kg/cm, and a minimum burst pressure of 60 bar. The anti-static option further elevates user safety during operations.

Versatile Design and Applications

The sand blasting hose is available in inner diameters from 12 mm to 50 mm and standard or customizable lengths. Its construction caters to a range of applications including industrial cleaning, surface preparation, and rust removal. Choose between plain or corrugated finishes and select end fittings as required, ensuring compatibility with your equipment and processes. The hose is ozone-resistant and flexible across a temperature range of -40C to +70C.

Compliance and Quality Assurance

Manufactured as per IS 5894 / IS 3499 or as specified, each hose undergoes stringent quality checks. With negligible shrinkage, minimal water absorption, and consistent wall thickness (3 mm to 7 mm), the product aligns with industry standards for safety and reliability. Its smooth or wrapped surface ensures ease of handling. The compound blend of natural and synthetic rubber enhances its performance in rugged work environments.

FAQs of Sand Blasting Hose:

Q: How is the sand blasting hose constructed to ensure high durability?

A: The hose features a black, smooth, inner tube made from highly abrasion-resistant natural rubber, reinforced with multiple layers of high-tensile synthetic textile plies. The outer cover is made from a robust, weather- and abrasion-resistant rubber compound, providing long-lasting performance even in harsh industrial environments.Q: What are the recommended working and burst pressures for this hose?

A: Depending on the size, the sand blasting hose can safely operate within a working pressure range of 12 to 25 bar. It has a minimum burst pressure of 60 bar, ensuring enhanced safety and reliability during demanding sand blasting tasks.Q: When should I choose plain versus corrugated or custom fittings for the hose?

A: The plain hose is ideal for standard, straight runs, while the corrugated option provides added flexibility for maneuvering around tight bends. End fittings, whether plain or custom-specified, should be selected based on compatibility with your sand blasting equipment and operational requirements.Q: Where can this sand blasting hose be applied effectively?

A: This hose is widely used for sand blasting in industrial cleaning, rust removal, and surface preparation tasks across manufacturing and maintenance environments. Its abrasion resistance and flexibility make it suitable for a broad array of industrial applications.Q: What process should be followed for installing the hose securely?

A: Ensure the hose is installed with the appropriate end fittings as specified and that the minimum bending radius (six times the nominal bore) is respected. Regularly inspect for wear, and replace or service as necessary according to the manufacturers guidelines for safe and effective operation.Q: What are the benefits of the hoses anti-static and ozone-resistant properties?

A: The anti-static feature reduces the risk of static electricity build-up, contributing to a safer working environment in environments with flammable materials. Ozone resistance prevents premature aging and cracking, extending hose life even when exposed to outdoor elements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber & Rubber Products Category

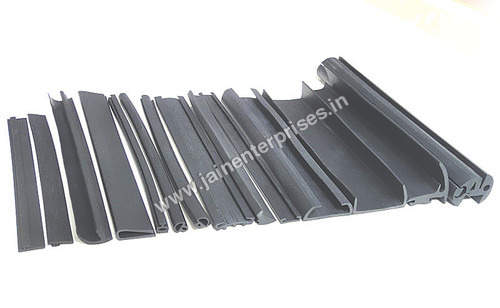

EPDM Rubber Profiles

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : Custom sizes available

Natural Rubber : 0% (100% synthetic EPDM)

Resistance level : Excellent resistance to weather, ozone, UV, steam, and chemicals

Tolerance : 0.5 mm

Rubber Profiles for Aluminum Doors

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : Standard and customized

Natural Rubber : Available upon request

Resistance level : High UV & ozone resistance

Tolerance : 0.5 mm

Rubber Beading

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : Standard, Custom sizes available

Natural Rubber : Available as Natural and Synthetic rubber

Resistance level : High to Weather, Ozone, Chemicals

Tolerance : 0.2 mm

Chemical Hose

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : Available from 12 mm to 150 mm inner diameter

Natural Rubber : Synthetic or natural rubber option

Resistance level : High resistance to chemicals & corrosion

Tolerance : 0.5 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese