Silicone gaskets

Silicone gaskets Specification

- Pressure Resistance

- Up to 60 Bar

- Vaccum Range

- Up to 1x10 Torr

- Hardness

- 30, 40, 50, 60, 70 Shore A

- Standard

- ASTM D2000 / IS / DIN

- Gasket Coefficient

- Low friction (Specific value on request)

- Working Temperature

- -60C to +230C

- Medium

- Air, Water, Chemicals, Oils

- Thickness

- 1 mm to 10 mm

- Type

- Flat / O-ring / Custom Profile

- Temperature Resistance

- Up to 230C Continuous

- Material

- Silicone Rubber

- Shape

- Ring / Circular

- Outer Ring

- Available / Optional

- Inner Ring

- Available / Optional

- Application

- Sealing, Insulation, High Temperature Gasketing

- Technology

- Compression Moulded

- Density

- 1.1-1.25 g/cm³

- Water Absorption

- <1%

- Surface Finish

- Smooth or Textured

- Elongation at Break

- 300% - 700%

- Chemical Resistance

- Resistant to acids, bases, oils, solvents

- Tear Strength

- 18 - 40 N/mm

- Compression Set

- 15% - 25% (22h @ 175°C)

- Color Options

- Red, White, Translucent, Blue, Custom

- Dielectric Strength

- >20 kV/mm

About Silicone gaskets

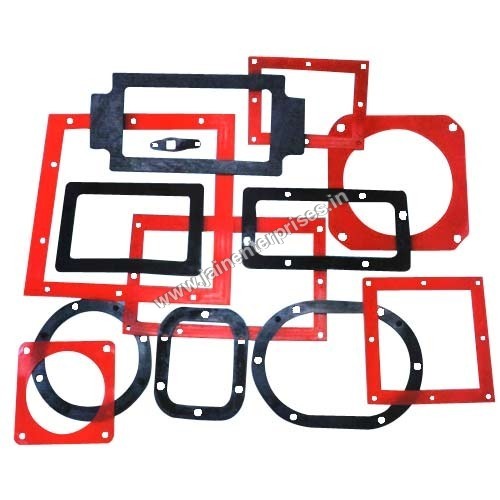

Silicone Gaskets

Leveraging on our uninterrupted activity of production, our company is the reputed manufacturer and exporter of the Silicone Gaskets. For manufacturing these gaskets in accordance with industry specific need, we source high grade quality materials from the leading vendor base. Used in chemical, oil, petrochemical and gas industries, these gaskets are suitable for sealing purpose. Our panel of expert quality analyzers duly test these Silicone Gaskets on varied quality norms to offer quality range to clients.

Features:

- Light weight

- Oil resistant

- Durability

Excellent Chemical and Temperature Resistance

Designed to handle harsh environments, silicone gaskets resist acids, bases, oils, solvents, and water absorption below 1%. Their robust material properties ensure stable performance across a wide temperature range from -60C to +230C, with a continuous operating threshold up to 230C and pressure resistance up to 60 Bar.

Customizable Design and Color Options

These silicone gaskets are available in standard shades like red, white, translucent, and blue, with bespoke color possibilities upon request. Shapes can be tailored to flat, O-ring, circular, or custom profiles, accommodating specific installation needs. Optional inner and outer rings further enhance design versatility for unique sealing demands.

FAQs of Silicone gaskets:

Q: How are silicone gaskets manufactured for specialized applications?

A: Silicone gaskets are produced using compression moulding technology, allowing precision in shape and thickness. This process enables customization to industry-specific standards such as ASTM D2000, IS, and DIN, making the gaskets suitable for specialized sealing and insulation tasks.Q: What benefits do silicone gaskets offer in chemical and high temperature environments?

A: These gaskets provide excellent resistance to acids, bases, oils, and solvents, and can withstand temperatures from -60C up to +230C continuously. Their low water absorption and stable mechanical properties, like high tear and dielectric strength, ensure durability and consistent sealing in demanding conditions.Q: When should I use a smooth versus a textured surface finish on silicone gaskets?

A: A smooth finish is ideal for achieving a tight, uniform seal in flat or highly polished mating surfaces, helping to minimize leakage. A textured finish may be beneficial for applications where additional grip or irregular surface engagement is required, improving overall gasket performance in dynamic environments.Q: Where can these silicone gaskets be used effectively?

A: They are widely used in industries such as automotive, food processing, pharmaceuticals, and electronics for tasks like high temperature sealing, insulation, and gasketing. Their resistance to various mediaincluding air, water, chemicals, and oilsmakes them suitable for both indoor and outdoor applications.Q: What options are available for customizing the shape and hardness of the gaskets?

A: You can select from ring, circular, O-ring, flat, or custom profile shapes to fit specific installations. Hardness levels can be chosen between 30 and 70 Shore A, tailoring compression and flexibility to the applications sealing requirements.Q: How does the gasket perform under pressure and vacuum conditions?

A: Silicone gaskets maintain integrity under pressures up to 60 Bar and function effectively in vacuum environments up to 1x10 Torr. Their robust design and low compression set make them reliable in both high-pressure and deep vacuum scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Gaskets Category

Rubber gasket

Application : Sealing in pipelines, flanges, plumbing and industrial equipment

Technology : Molded / Die Cut

Medium : Other, Water, Oil, Chemicals, Steam

Temperature Resistance : Up to 120C

Thickness : 1 mm to 10 mm

Type : Flat Gasket

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese