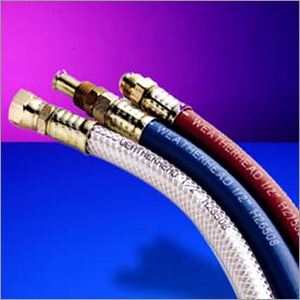

Thermoplastic Hoses

Price 100 INR/ Meter

Thermoplastic Hoses Specification

- Connection Type

- Crimped Fittings

- Shape

- Round

- Reinforcement

- High tensile synthetic fiber

- Medium

- Oil, Water, Air, Chemical applications

- Hardness

- Shore A 95 2

- Material

- Polyamide (Inner Tube), Polyurethane (Cover)

- Pressure

- Up to 880 bar (varies by type)

- Inside Diameter

- 5 mm to 25 mm

- Outside Diameter

- 11 mm to 34 mm

Thermoplastic Hoses Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Week

About Thermoplastic Hoses

Thermoplastic Hoses.

We are instrumental in offering an extensive range of Thermoplastic Hoses. To meet the international quality standards, these hoses are designed and developed under the strict supervision of our experienced professionals, employing latest technology. Post-production, these hoses are stringently checked on various parameters to ensure zero-defect. These hoses are suitable for high pressure hydraulic, chemical industries, rescue tools, measuring & control techniques and mining & offshore applications. Thermoplastic Hoses are known for chemical & abrasion resistance, easy to handle nature, simple installation and perfect finish.

Other information:

We have thermo plastic hoses for

- Pneumatic tool hose

- Super spray hose

- Welding Hose

- Super Rock drill hose

- Car Wahing Hose, and

- Heavy duty air/Water hose

Typical Applications for these hoses are

- High pressure hydraulic

- High pressure gas and liquid transfers

- Chemical industries

- Rescue tools

- Measuring and control techniques

- Surface treatments (Paint spray applicaiton)

- Gen Working hydraulics

- Lubrication techniques

- Mining applications

- Offshore Applications

- Tube cleaning operations

- General engineering

- Hose bundles/umbilical

- Air-conditioning

- High Pressure cleaning

We are paying special attention and using new and better techniques in the manufacturing of our products due to which our products have few advantages over other products, few of them are mentioned below

- The concept of reinforced thermoplastic construction offers outstanding performance

- The special characteristics of Industrial thermo plastics are used to achieve low weight, ease of handling, compactness chemical and abrasion resistance, long continuous lengths, colour etc.

Other Features

- All hoses are available as twin and triple line hose configurations.

- Hose assemblies with permanently fitted end fittings are available

- Specific cover colors on request for bulk quantity order.

- Pin picked cover available for gas applications.

Precision Engineering for Demanding Environments

Our thermoplastic hoses deliver reliable performance under extreme pressures up to 880 bar, making them suitable for critical industrial tasks. The carefully selected diameters and Shore A hardness ensure optimal flexibility and wear resistance, even during prolonged use.

Superior Material Composition and Reinforcement

The unique combination of a polyamide inner tube, polyurethane cover, and high tensile synthetic fiber reinforcement provides outstanding chemical resistance and durability. Crimped fittings offer secure, leak-proof connections, supporting various media including oil, water, air, and chemicals.

Wide Application Range for Industrial Needs

Manufactured in India, these hoses serve as versatile solutions for hydraulic, pneumatic, and chemical transfer systems. Their robust construction and high-performance materials make them a trusted choice for industries requiring efficiency and longevity.

FAQs of Thermoplastic Hoses:

Q: How should thermoplastic hoses be installed to ensure optimal performance?

A: Installation should be carried out by trained personnel, using the correct crimped fittings to prevent leaks or damage. Avoid sharp bends and ensure the hose is compatible with the applications pressure requirements for long-lasting reliability.Q: What types of media can these thermoplastic hoses safely handle?

A: These hoses are designed for safe transfer of oil, water, air, and various chemicals, owing to their durable polyamide and polyurethane construction and high chemical resistance.Q: When is it advisable to replace thermoplastic hoses?

A: Replacement is recommended if the hose shows signs of wear, such as cracks, softness, loss of flexibility, or visible damage, or at the manufacturers suggested interval for high-pressure use.Q: Where can these hoses be utilized in industrial settings?

A: They are suitable for use in hydraulics, pneumatic controls, chemical process handling, and general fluid transfer tasks where durability and high pressure resistance are essential.Q: What is the manufacturing process for these high-pressure hoses?

A: The process involves extruding polyamide for the inner tube, braiding the synthetic fiber reinforcement, and applying a polyurethane cover. Crimped fittings are then attached for a secure, leak-resistant connection.Q: How does the hose design benefit industrial users?

A: The hoses robust materials, strong reinforcement, and secure fittings combine to minimize downtime, reduce maintenance costs, and ensure high-pressure resistance for efficient and safe operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese